Due to its methane content, BioGas is a combustible gas mixture with an energy content of 6kWh per m3. In special BioGas engines (ICEs) BioGas is converted to renewable electrical power.

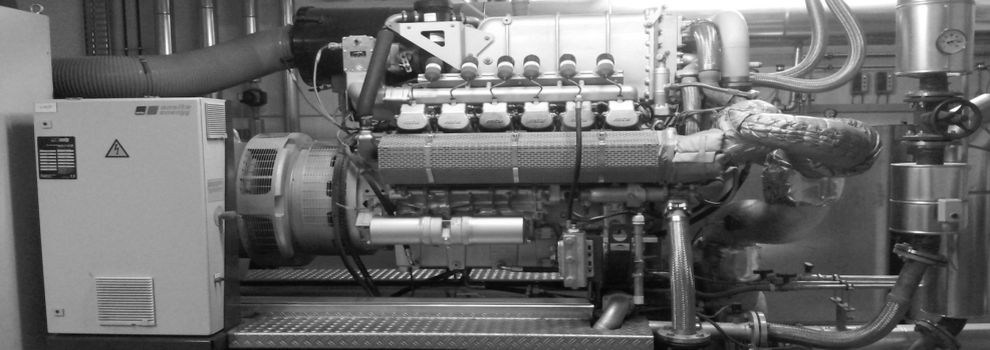

Advanced BioGas Engines: 43% Electrical Efficiency & 20 Years of Useful Life

Advanced BioGas engines with combined heat & power (CHP) systems convert BioGas into renewable energy in the form of

- Electrical Power

- Thermal Power (heating or cooling) and

- Steam

CHP systems utilize the high-temperature engine exhaust gas (>800°C) to generate additional electrical power. While standard BioGas engines have electrical efficiencies of 25% to 35%, CCI applies the best available CHP BioGas engines with electrical efficiencies of 43%. In addition to 30% to 50% more electrical output, advanced BioGas engines offer a useful technical life of 180,000 hours or over 20 years.

Proprietary BioGas Cleaning Technology: 99% H2S removal

These advanced BioGas engines are high-tech installations that are very sensitive to hydrogen sulfide (H2S) contamination and humidity in raw BioGas. CCI therefore uses a highly efficient proprietary technology to remove H2S, water & other impurities from the raw BioGas.

This cleaning technology protects the valuable BioGas CHP engines while ensuring their optimal performance, longevity as well as low operating & maintenance costs.

BioGas-to-Power with CHP BioGas Engines: 72 kWhe/TFF | 8,300 FLH per year

CCI's advanced A+ BioGas production and cleaning technologies permit the use of the most advanced BioGas engines on the market with maximum electrical efficiency and minimum maintenance. With this integrated production chain (A+ BioGas production + proprietary BioGas filter + advanced CHP BioGas engines) palm oil mills can produce an average of 72 kWhe per ton of fresh palm fruit (TFF), a 60% increase compared to the typical 45kWhe/TFF in standard covered lagoon systems with standard BioGas engines.

The consistently high quality of BioGas generated in CCI's A+ BioGas plants allows our BioGas engines to be operated with a minimum of maintenance, resulting in a continuous operation of up to 8,300 full load hours per year and over 20 years of top performance.

Power Production Cost: 30% savings per kilowatt hour electric

The combination of these integrated high-tech, high-yield BioGas technologies enables us to produce electrical power at over 30% less cost per kWhe (kilowatt hour electric) than the leading competition.